Category

Zero Leakage Forged Steel A105 A350 Lf2 Body Soft Seat Primary Metal Seat Weld Overlay Inconel 625 Flange Floating and Trunnion Mounted Ball Valve

Package size per unit product 150.00cm * 150.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 15 days

Basic Info

| Model NO. | Q47 |

| Media | Oil |

| Material | Carbon Steel |

| Connection Form | Flange |

| Driving Mode | Worm Gear |

| Nominal Pressure | ANSI CLASS 150-900 |

| Channel | Straight Through Type |

| Structure | Fixed Ball Valve |

| Type | Fixed Ball Valve |

| Function | Blow-Down Valve, Relief Valve, Atmospheric Valve, Bypass-Valve |

| Temperature | Low Temperature |

| Standard | ANSI,DIN,JIS,GOST or Customized |

| Application | Industrial Usage, Water Industrial Usage, Household Usage |

| Construction | Single, Two and Three Pieces |

| Bore Design | Full Bore or Reduced Bore |

| Sealing | Soft and Metal-Seated |

| Connect | Flanged,Screwed, Socket-Weld |

| O Ring | Aed O Ring or Lip Seals |

| Seat Design | Primary Soft Seal or Secondary Metal Seal |

| Effect Seat | Single Piston Effect Seat or Double Piston Effect |

| Dbb | Double Block and Bleed |

| Stem | Blow out Proof Stem |

| Static Device | Anti-Static Device |

| Fire Safe Design | API 607, API 6fa,ISO 10497 |

| Soft Seat | Enp Coating, Base Material |

| Metal Seat | Inconel Overlay or Tungsten Carbide Coated |

| Body | Bolted Body or Welded Body |

| Special | Nace Mr0175 |

| Transport Package | Standard Export Packing Seaworthy |

| Specification | 1000*1000*1000 |

| Trademark | AEA VALVE or Customized |

| Origin | China |

| HS Code | 848180 |

| Production Capacity | 50000 Tons/Year |

Packaging & Delivery

Package size per unit product 150.00cm * 150.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 15 days (1 - 1 Sets)To be negotiated ( > 1 Sets)

Product Description

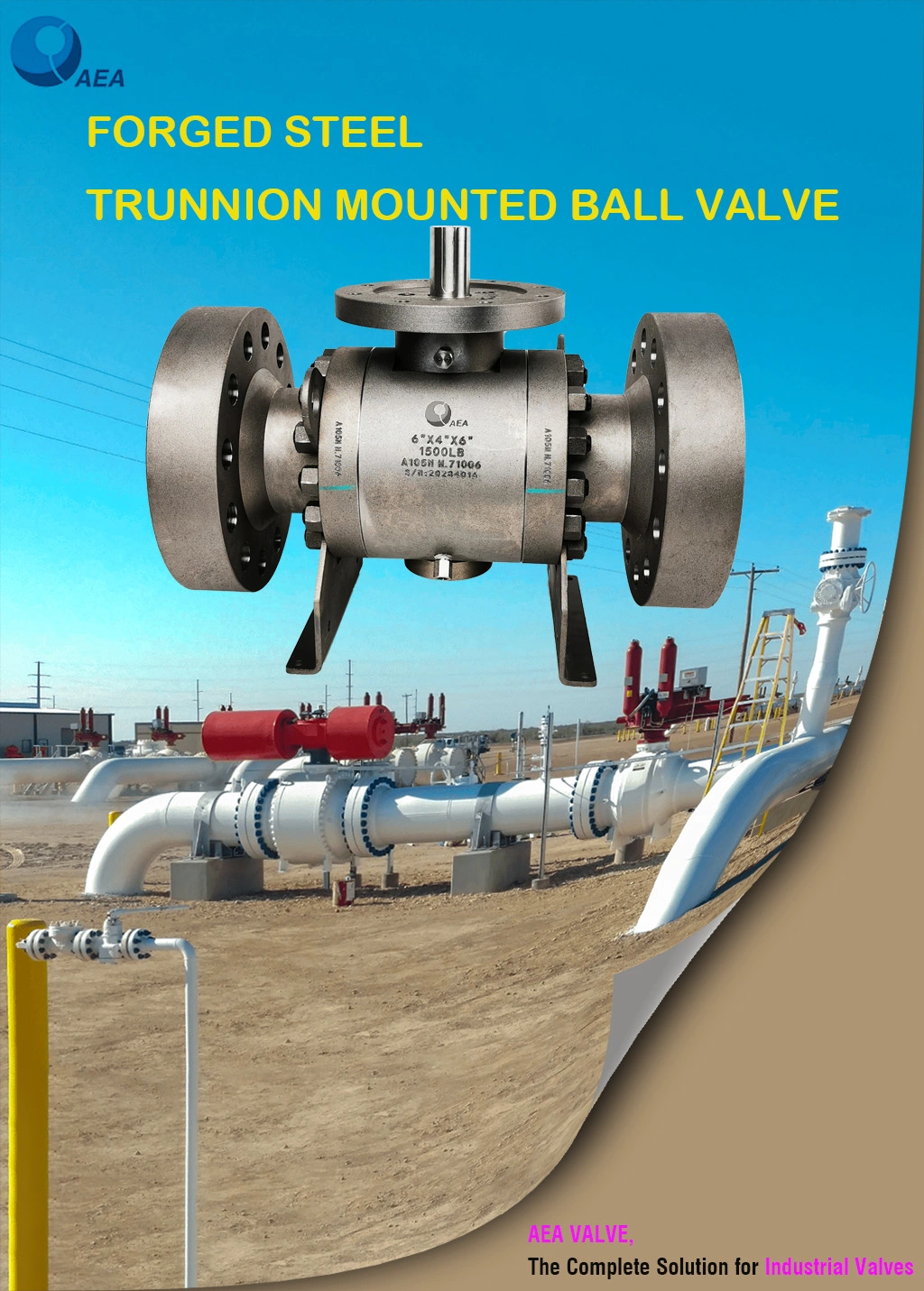

AEA Forged Steel Trunnion Mounted Ball Valve

| Size | 2" to 60" (50 mm to 1500 mm) |

| ASME Class | Class 150 to 2500 |

| Design Standard | API 6D |

Standards:

- Trunnion-mounted Ball Valve design complies to API 6D

- Valves offered with API 6D monogram

- Wide portfolio of Side-entry and Top-entry designs

- Fugitive emissions - Soft and Metal seated valves complies to ISO 15848-1, Class AH and BH

- Stem seal configurations tested to API 622 at Yarmouth Research labs, Maine, USA

- Firesafe design - Tested to API 607 and API 6FA

- CE Marking - Meets requirements of Pressure Equipment Directive 2014/68/EU, Annexure III, Module H

- PED Module B1 Design examination certificate (certified by DNV) available

- Atex - Meets requirements of Atex Directive 94/9/EC (ATEX), category 2 non-electrical equipment

- SIL3 - Safety Integrity Level SIL 3 certification to IEC 61508, certified by Exida/ TUV

- Valves successfully tested to Shell Design Evaluation Test, Procedure 77/300 for temperature -29 to 150 degree C (O rings) and -50 to 150 degree C (Lip seals)

- Pneumatic shell test conducted at 1.1 times rated pressure to check shell integrity, when required

Features that Add Value:

- Double block and bleed (DBB) feature - Valves are designed and tested for automatic cavity relief

- Anti-blowout stem design

- Coil springs used for consistent seat loading and lower operating torque

- Lip seals provided for low temperature services

- 2/3 stage Stem and 2 stage Body Joint sealing system; Primary O ring and Secondary graphite (in 3 stage stem, thrust washer is primary)

- Where tight shut off is required, Double piston effect (DPE) seats provided for redundancy in sealing

Versatile Solutions:

- Wide portfolio of Side-entry and Top-entry designs

- Options: Buried service, Cryogenic

- Offered with Electric, Pneumatic and Hydraulic Actuators

- In-house Tests Capabilities - Cryogenic Test, Pipe Bending Test, Vacuum Test and Fast Closure Test

Accessibility to all the valve internals from the top

In-line valve maintenance, without disassembling the valve from the pipeline

Reduces maintenance downtime

Body cover joint not exposed to pipeline stresses

Trunnion-mounted Ball Valves - Top-entry Design Special Features: Accessibility to all the valve internals from the top In-line valve maintenance, without disassembling the valve from the pipeline Reduces maintenance downtime Body cover joint not exposed to pipeline stressesValves - Top-entry Design

Special Features:

- Accessibility to all the valve internals from the top

- In-line valve maintenance, without disassembling the valve from the pipeline

- Reduces maintenance downtime

- Body cover joint not exposed to pipeline stresses

Trunnion-mounted Ball Valves - Top-entry Design

Special Features:

- Accessibility to all the valve internals from the top

- In-line valve maintenance, without disassembling the valve from the pipeline

- Reduces maintenance downtime

- Body cover joint not exposed to pipeline stresses