Category

OEM ODM PTFE PFA Coaed Disc CF8 CF8m SS304 SS316 Wcb Bronze API ANSI DIN JIS BS Standard Control Butterfly Valve Gate Valve Check Valve Y Strainer

Product Feature: Resilient seated butterfly valve is a Double Flanged design which can be used for dead-end service. Thi

Basic Info

| Model NO. | CBF02-TF01 |

| Work Pressure | Low Pressure (Pn<1.6mpa) |

| Working Temperature | Medium Temperature (120°C<T<450°C) |

| Material of Seal Surface | Soft Sealed |

| Valve Body | Casting |

| Standard | API609 En593 BS5155 En1092 ISO5211 |

| Application | Industrial Usage, Water Industrial Usage, Household Usage |

| Power | Manual, Electrical, Pneumatic |

| Body Material | Cast Iron/Ductile Iron/Wcb/CF8m/CF8/Al-Bronze |

| Disc Material | Di/Nylon/1.4469/1.4529/Saf2205/2507/CF8/CF8m etc |

| Seat Material | NBR/EPDM/PTFE/Viton/Silicone etc |

| Coating | Fbe Epoxy Coated |

| End Standard | Pn6/10/16/25/21/150lb/JIS5K/10K/As2129 Table D/E/F |

| Face to Face | En558;API609;DIN3202;ISO5752;BS5155;Awwa |

| Transport Package | Plywood Case or Carton |

| Specification | DN50-DN3000 |

| Trademark | WDS / WORLDS/OEM |

| Origin | Tianjin China (Mainland) |

| HS Code | 8481804090 |

| Production Capacity | 10, 000, 000PCS/Year |

Product Description

Product Feature:Resilient seated butterfly valve is a Double Flanged design which can be used for dead-end service. This butterfly valve series has many of the design features and benefits , such as high Cv ratings, minimum parts exposed to the line media, greater reliability and a proven record of long service life. A major design advantage of this valve product lines is international compatibility.

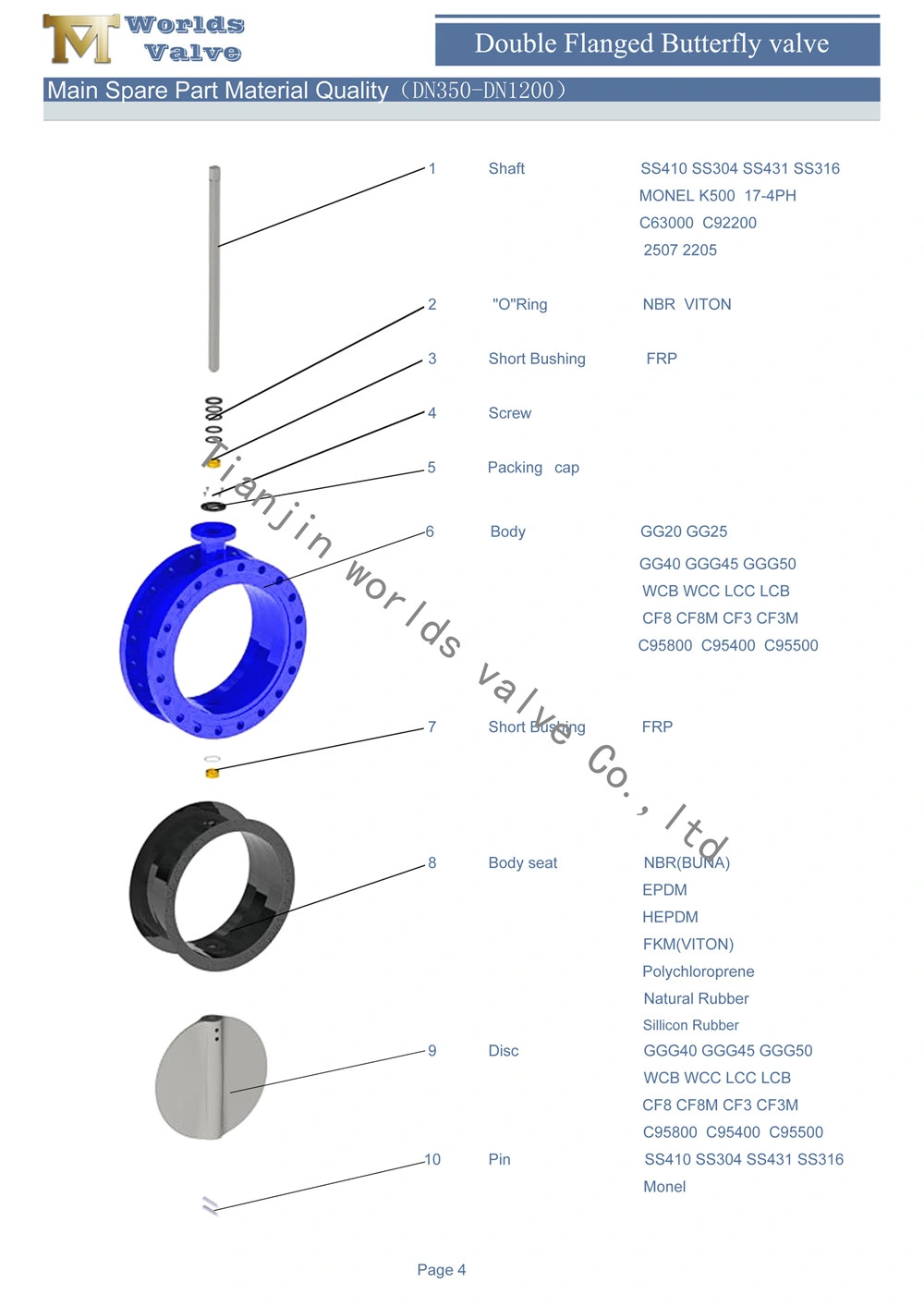

Material :

| BODY | CI, DI, WCB, WCC, LCB, LCC, CF8, CF8M, CF3, CF3M, C95400, C95800, SAF2205, SAF2507, F51, 1.4529^^ |

| DISC | CF8, 304, CF3, 304L CF8M, 316, CF3M, 316L, SAF2205, SAF2507, F51, 1.4529, C95400, C95500, C95800, MONEL^.. |

| SEAT | BUNA-N, NBR, EPDM, HYPALON, NEOPRENE, VITON, FKM, PTFE, RPTFE, TEFLON, NATURAL RUBBER^^ |

| STEM | F410, F420, F430, F431, F304, F316, MONEL 400, MONEL K500^^ |

Technical Parameters:

| Size | DN32-DN600 | DN650-DN3000 |

| Working pressure | 16Bar | 10Bar |

| Shell | 24Bar | 15Bar |

| Seal(Air) | 6Bar | 6Bar |

| Operating Temperature | -40ºC~+160ºC | |

| Operating Environment | Ballast and bilge system Chemical processingDesalination plants Drilling rigs Drinking waterDry powder Food and beverage Gas plantsHAVC Mining industry Paper industry Sand handling Seawater Sugar industryThermo technical water treatment Waste water | |

| Driving method | Hand Lever Worm Gear Electric Pneumatic | |

**COMPANY INTRODUCTION

**Company Goal : OEM service for world-famous valve brand

**Design & Development ability -- SolidWorks, Pro / E, AutoCAD etc

**Dimension Measurement &Inspection

**Assembly Workshop

**Packaging

**Certificates -- CE ISO WRAS ACS certificates